Basic concepts and definitions

The most responsible operation in the process of construction of fiber-optic, predetermining the quality and range is the installation of optical fibers. Such a combination of fibers and installation cables are produced in the manufacturing process as well as during the construction and operation of cable lines.

Installation is divided into permanent (fiber welding) and temporary (plug connectors). Fiber optic connectors typically are valves designed for adjusting and fixing the fibers to be connected, as well as mechanical protection for the splice.

The main requirements for connectors are:

- simple structure;

- small transient loss;

- resistance to external mechanical and climatic influences;

- reliability;

- In addition to the detachable connectors are required constancy of parameters during re-docking.

Insertion loss connection of optical fibers in a cable transmission path, are divided into external and internal.

External referred to the losses associated with the features of the connection method, including the preparation of the ends of optical fibers, and comprising lateral displacement of the core, diversity ends, the slope of the axes, the angle of the fiber end face, the Fresnel reflection.

I nternal losses are associated with the properties of the resulting optical fiber and, for example, variations in core diameter, numerical aperture, the refractive index profile, netsirkulyarnostyu core Concentricity core and cladding.

Internal loss

Internal losses are a consequence of joining two dissimilar optical fibers having different diameters basically numerical aperture and

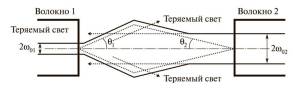

When light propagates forward (left to right) at the junction loss is zero, in the reverse direction of propagation of light rays enters the peripheral portion of the sheath of the optical fiber with a smaller diameter and is lost.

The single-mode optical fibers internal losses are independent of the direction of transmission and are determined only by the mismatch of the mode field diameters of mating optical fibers.

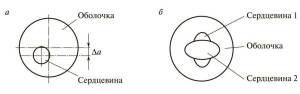

A possible source of loss is also a non-concentric placement of the core within the reflective shell. That is, the optical fiber core is offset relative to the central point of the optical fiber. Also additional losses in the fiber may make non-ideal cross-sectional shape in the optical fiber cable.

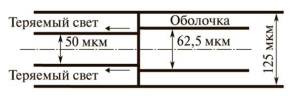

Also, the internal loss can be caused by inequality-diameter optical fiber membranes. What can you say when the mechanical connection of optical fibers.

Internal losses due to:

а — Non-Concentricity;

б — ellipticity form cores.

Internal losses due to inequality shells diameters

External loss

External losses are due to four main reasons:

- radial displacement of optical fibers;

- angular displacement;

- axial displacement;

- ends quality.

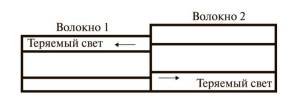

The optical fiber in the connector must be located along the central axis. If one central fiber axis does not coincide with the axis of the other, inevitably appear due to the loss of radial displacement. Also, if the connection of two optical fibers is divided slight clearance (axial displacement), the fiber becomes susceptible to additional loss mean .. That effect is due to Fresnel reflection, which is related to the difference in refractive index of the medium and the fibers in the gap (usually air).

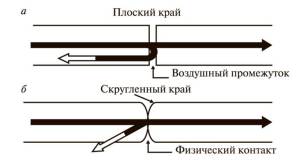

Fresnel reflection:

а — in the absence of an air gap;

б — in the presence of the air gap.

The reflection at the interface of two media characterizes the I parameter R, which represents the ratio of reflected power to the power of the input wave.

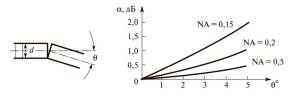

Also, optical fibers treated chips should be perpendicular to the fiber axis and parallel to each other when connected. Losses associated with the angular orientation of optical fiber misalignment relative to each other (angularly offset), shown in Fig. The loss in this case is also determined by the numerical aperture NA.

Losses at an angular displacement

Installation of optical fiber

In the process of mounting the optical line made stationary (non-detachable) connection of separate lengths of cable construction. When you enter the building FOC regenerative or for multiple connection and disconnection with the optoelectronic equipment used plug connectors - connectors. Connection of optical fibers is carried out in sequence. Initially being prepared end faces of optical fiber and then splice is made.

Prior to connecting two optical fibers requires some preparation fiber ends, which consists in removing the primary protective coating from the fiber preform, followed by a smooth end face grinding or chipping. To remove the primary coating from the optical fiber can be used as chemical cleaning methods, and mechanical.

Chipping training called optical fiber end with the scratching and the subsequent fault. Ideally, peeling of the optical fiber should be perpendicular. Any deviation must not exceed 1—2 о .

In conjunction with single-mode flat polished end faces and in the presence of an air gap between the fibers of mating portion of the energy is reflected back to the source and return loss generates. One way to reduce the return loss is the rounded ends of the optical fibers at grinding.

Splicing is carried out by welding or by a mechanical splice. As a tool used by an electric arc occurring between the electrodes, the flame of a gas burner or a laser. The operating principle of welding machines are divided into units with manual, semi-automatic and automatic. Mechanical splicing divided into active or passive depending on whether the optical fiber alignment is performed to optimize the loss or not.

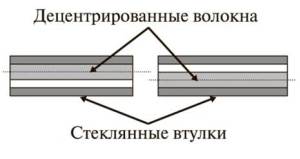

In mechanical splicing of individual fibers is dominated by three technologies:

- four rod guides the company TRW;

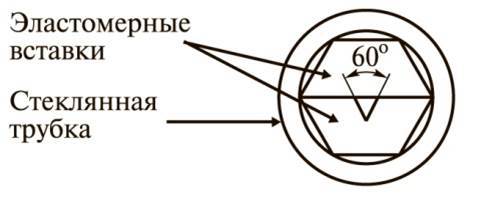

- elastomeric aggregates company GTE;

- rotatable splice of AT & T.

Connection of optical fibers by means of four guide rods

Connection of optical fibers using an elastomeric splice

The connection of optical fibers using a rotary splice

Compound optical fibers via lock Fibrlock

Main method of connecting active network equipment with fiber-optic line is the use of optical connectors, to be connected by an optical adapter that is installed in the optical cross. Inside the optical cross boiled soft optical fiber pigtails are to terminate with optical connectors.

The optical connector - this is a mechanical device designed for multiple connections. It provides a quick way to reconfigure the equipment, check the fiber connection to sources and destinations of the world. Connector for connecting the single optical fiber consists of two main parts: a connector and a connector.

Connectors: а — FC; б — ST; в — SC.