- 1. Classification of fiber optic cables

- 2. Basic requirements for the fiber-optic cable, and the material of its main components

- 3. Typical designs of optical fiber cables

- 4. The construction of the FOC with the free fiber bundle

- 5. The construction of the FOC core with core

- 6. Design ribbon fiber optic cable

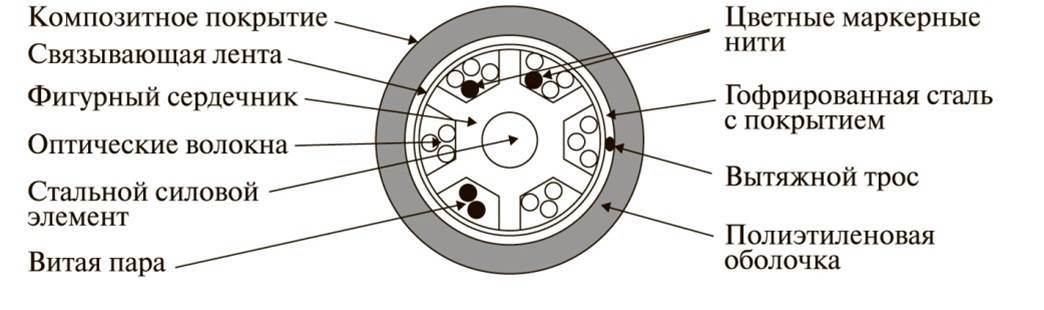

- 7. The construction of ocean-going fiber optic cable

- 8. Fiber Optic Cables urban telephone networks

- 9. Fiber-optic cables for internal wiring

Classification of fiber optic cables

Fiber-optic cables (FOC) - a cable products, containing a number of optical fibers and the reinforcing member enclosed in a common envelope, on top of which, depending on the operating conditions of the protective cover can be imposed.

Fiber-optic cables are classified by purpose and conditions of use, as shown in the figure below.

Since FOC less durable than electric cables, they must be protected from the harmful effects of the environment and human activities, which include mechanical stress (tension, bending, compression, torsion, shock, vibration); temperature changes; water penetration.

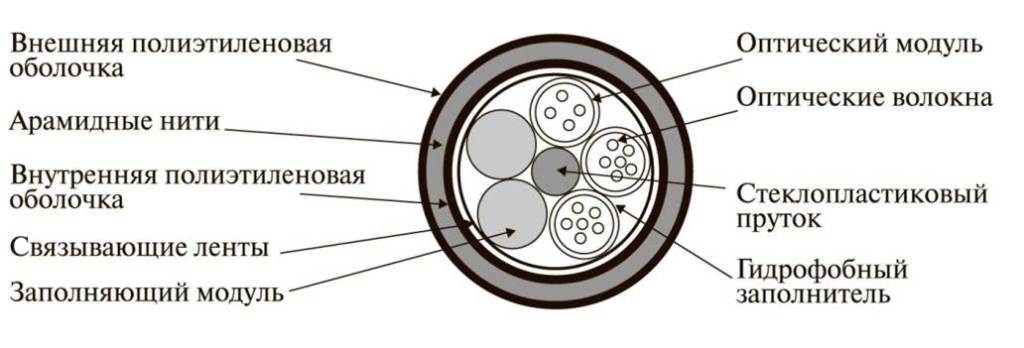

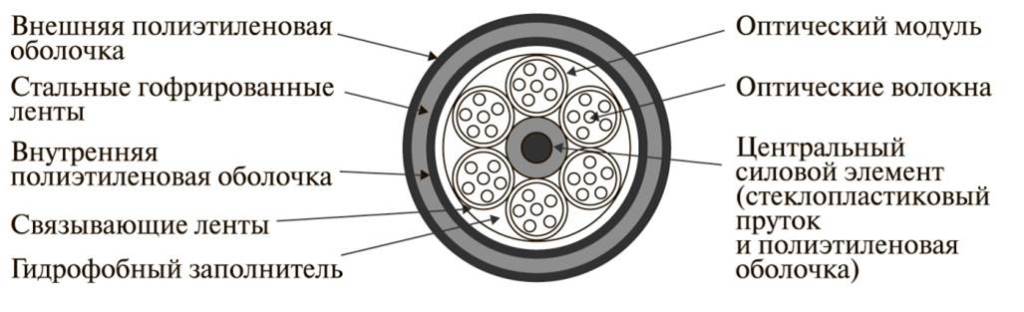

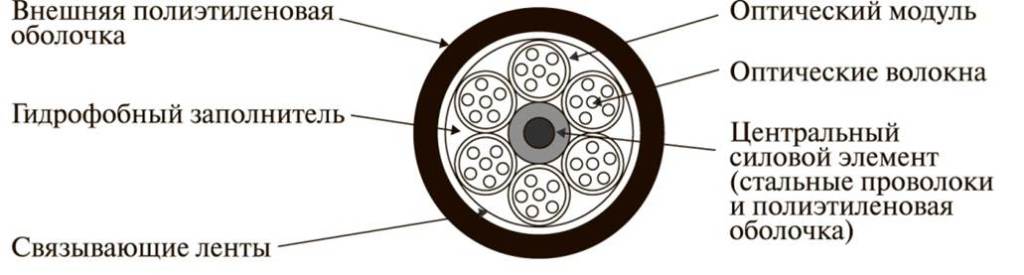

Fiber-optic cable can consist of the following components:

- Outer PE shell - protects the cable from external influences;

- Armid thread - protects the cable from the squeezing and stretching;

- Inner polyethylene shell - separates the optical module from armid shell and the outer shell;

- Binding tapes - connect optical modules in the overall braid;

- Filling unit - empty unit without the optical fiber cable is designed to form a shape;

- Optical module - module with optical fibers. Usually there is one module 8 to the fibers;

- Optical fibers;

- Fiberglass bars - reinforcing the central element, also protects the cable from stretching. It is used often in self-supporting cables;

- **The hydrophobic filler - filler, protects from moisture.

Basic requirements for the fiber-optic cable, and the material of its main components

Common basic requirements for physical and mechanical characteristics of the fiber optic cable are:

- high tensile strength;

- moisture resistance;

- sufficient buffer protection to reduce losses caused by mechanical stresses;

- thermal stability in the operating temperature range (–40—+50 о С);

- flexibility and the possibility of laying on the actual routes;

- radiation resistance;

- chemical and impact resistance;

- ease of installation and gaskets;

- reliability in operation for 20 years.

Also during the design must take into account the relative POC location strength members and optical fibers. There are two main options for such a mutual arrangement:

- In the first reinforcing member is located in center of the cable, and fiber - concentrically relative to the central element.

- In the second optical fibers are arranged in the center and power elements - around

Typical designs of optical fiber cables

Currently in different countries developed and produced a large number of construction POC. The most widely used group of four cable designs:

- with a free tube;

- free-fiber bundle;

- with core-core;

- belt type.

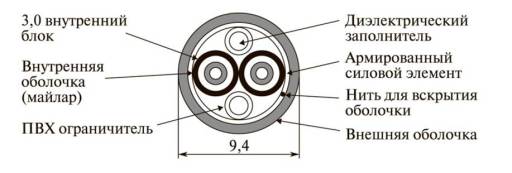

The construction of the FOC with the free fiber bundle

With this structure, the optical fiber bundles are placed freely inside the core tube. This design reduces the tensile, compressive and compressive loads on the optical fibers. Fume cables are used for the convenience of cutting the outer sheath of the optical cable.

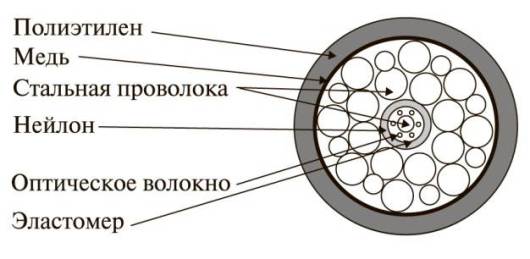

The construction of the FOC core with core

With this structure, there is a core shaped with cavities for placing the optical fibers. The advantage of this type of construction is that the center of figure of the core is a steel strength member that receives the compressive and tensile impact.

Design ribbon fiber optic cable

In this structure, all the optical fibers are combined into bands, which are located within the core tube.

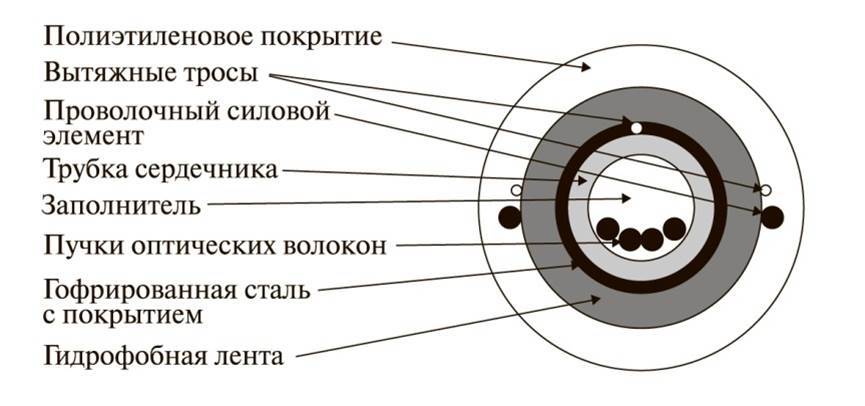

The construction of ocean-going fiber optic cable

It designs cables laid on the seabed, there are special requirements. Cables of this type are experiencing particularly heavy loads. Therefore, more than 90% of the data cable constructions make up the protective and reinforcing elements.

Fiber Optic Cables urban telephone networks

Cables used for urban telephone networks have, as a rule, lightweight design, as laid in cable ducts, pipes, reservoirs and inside buildings. Such cables are designed according to the principle of free tube with a large number of optical fibers in each module.

JSC "Samara Optical Cable Company" FOC makes the city the following brands: OKL 01 OKL 02..

NF JSC "Wiring harness" produces urban brands EQA OK M M ACS (TU 16.K12 16, 97).

"Plant Saransk Cable" in addition to long-distance FOC has mastered the production of cables and urban telephone networks of the following brands: JAG (laying in cable ducts) and CPR (laying directly in the ground).

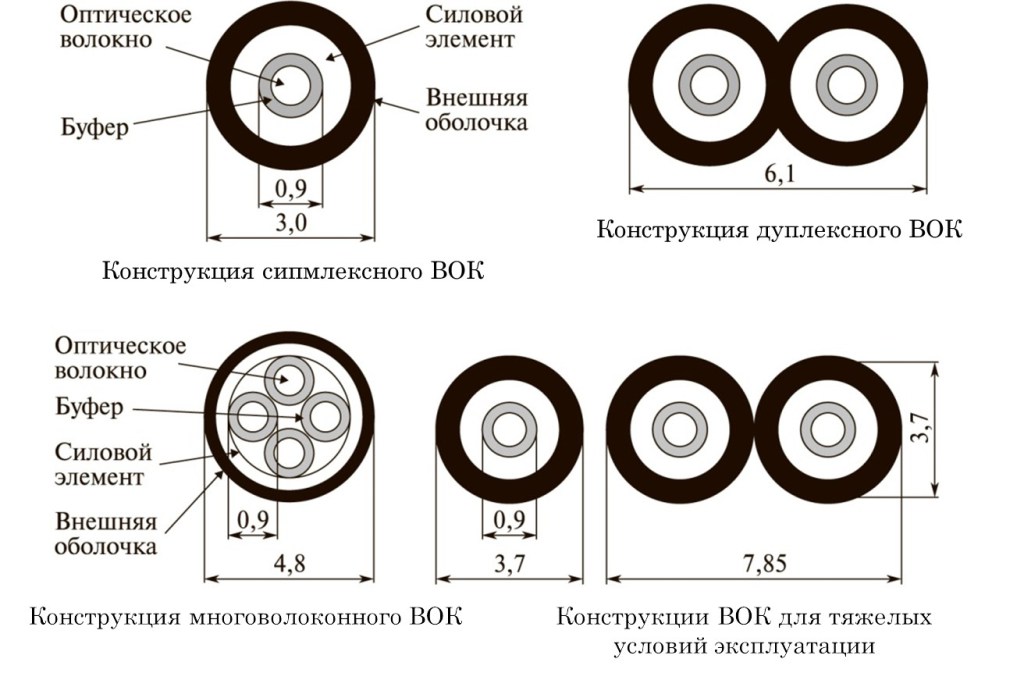

Fiber-optic cables for internal wiring

The design of the fiber-optic cable for internal wiring consists of the following main elements:

- an optical fiber;

- buffer shell;

- power element;

- outer shell

Cables are designed for internal wiring, divided into:

- Simplex cables;

- duplex cables;

- multi-fiber cables;

- cables for heavy duty;

- fireproof cables.